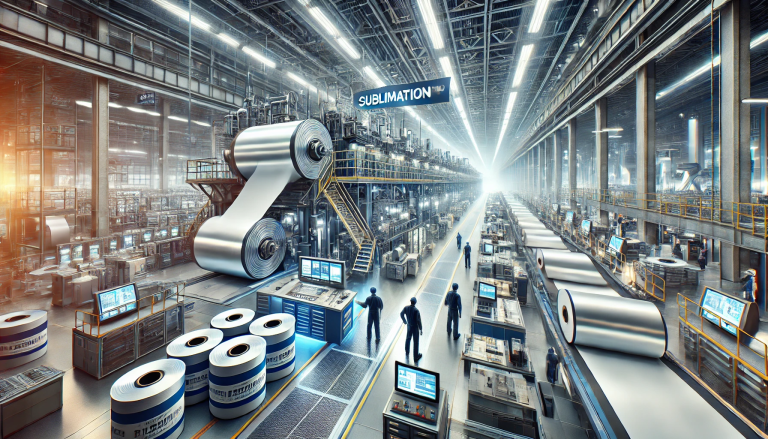

Using fabric transfer paper for sublimation printing is a topic that intertwines the realms of fabric artistry and modern printing technology, offering a nuanced exploration of materials, methods, and outcomes. This discourse aims to shed light on the compatibility and efficiency of using fabric transfer paper within the sublimation process, delineating technical aspects, potential benefits, and limitations.

Waht is Sublimation printing

Sublimation printing is a method that transfers a design from specially coated paper to fabric using heat and pressure. The process involves turning solid dye particles into gas using high temperatures, bypassing the liquid state, and embedding the dye into the fabric’s fibers. This results in vivid, durable, and detailed prints that are fully integrated into the fabric. Sublimation is primarily effective on polyester or polyester-coated materials, as the process requires synthetic fibers to properly bond with the dye.

What is fabric transfer paper?

Fabric transfer paper, on the other hand, is a broader category encompassing various types of papers designed to transfer printed designs onto fabric. There are two primary types of transfer paper: one for inkjet printers and another for laser printers. Each type is coated with a unique substance that allows the transfer of ink or toner onto fabric when heat is applied. These papers are typically used with cotton or blended fabrics and are not specifically designed for the sublimation process.

The core question is whether fabric transfer paper can be used for sublimation printing. The answer hinges on understanding the distinct requirements and outcomes of the sublimation process compared to traditional transfer paper applications.

Firstly, sublimation requires a specific type of paper that is coated to release the dye when heated. This paper is designed to work at the temperatures necessary for sublimation (usually around 400°F or 204°C) and to release the dye gas efficiently into the fabric. Standard fabric transfer papers, however, are not coated with the same materials and may not withstand the high temperatures required for sublimation. They are designed to work at lower temperatures to transfer ink or toner onto the surface of the fabric, not to embed dye into the fibers.

Secondly, the chemical composition of the dyes used in sublimation is designed to bond with polyester fibers. Fabric transfer papers for inkjet or laser printers are intended to transfer inks or toners that sit on the fabric’s surface rather than bonding with the fibers. This difference in chemical interaction means that even if fabric transfer paper could withstand the sublimation temperatures, the inks or toners used with these papers would not produce the same quality or durability of print as sublimation dyes.

Moreover, the quality and durability of prints achieved through sublimation are significantly higher than those achieved with standard transfer papers. Sublimation prints are less prone to fading, cracking, or peeling off since the dye becomes part of the fabric. In contrast, designs transferred using regular fabric transfer papers may crack, fade, or peel over time with washing and use.

In conclusion

while it is technically possible to use fabric transfer paper in a sublimation printer, the process and the outcomes would not align with the fundamental principles and advantages of sublimation printing. The specialized nature of sublimation paper and dyes, designed to chemically bond with polyester fibers under high heat, is crucial for achieving the vibrant, long-lasting prints characteristic of this method. Therefore, for those seeking the high-quality results offered by sublimation, investing in the correct supplies—specifically designed sublimation paper and dyes—is essential. By doing so, artists and printers ensure that their creations embody the desired aesthetics and durability, preserving the integrity and beauty of their work over time.