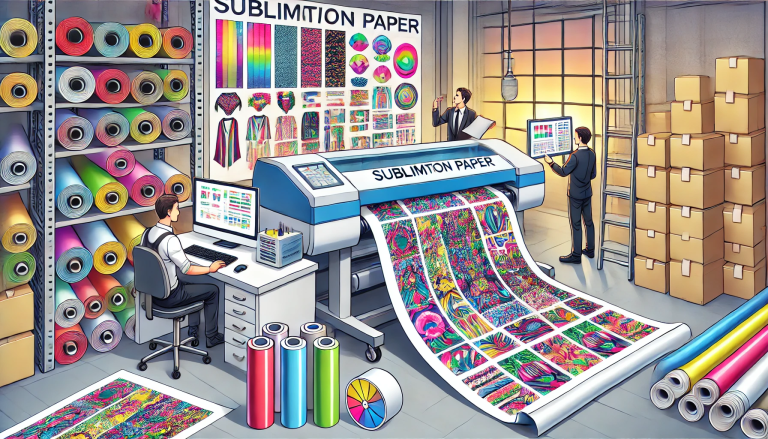

Sublimation paper and transfer paper are essential components in the world of custom printing, serving as the mediums that carry designs from imagination to reality on various substrates. Despite their similar roles in the printing process, these two types of paper possess distinct characteristics, applications, and compatibility with different types of inks and materials. This article delves into the nuances of sublimation paper and transfer paper, highlighting their differences, advantages, and suitable applications to provide a comprehensive understanding of their roles in the printing industry.

Understanding Sublimation Paper

Sublimation paper is a specialized paper designed for use in dye sublimation printing, a process that involves transferring a design from the paper to a substrate using sublimation ink and heat. The key feature of sublimation printing is the transition of the ink from a solid to a gas without going through a liquid phase, allowing it to bond with polyester-coated or polyester-based materials. This results in high-quality, durable prints that are embedded within the substrate rather than sitting on top of it.

Sublimation paper is coated with a special layer that holds the sublimation ink. This coating plays a crucial role in the transfer process, as it controls the release of the ink when heated. The success of sublimation printing heavily relies on the quality of the paper, the type of ink used, and the compatibility of the substrate. Ideal substrates for sublimation printing include polyester fabrics and polymer-coated items such as mugs, mouse pads, and photo panels.

Exploring Transfer Paper

Transfer paper, on the other hand, is a versatile medium used to transfer printed designs onto various substrates, including textiles, ceramics, and wood, through the application of heat and pressure. Transfer papers are available in different types for use with either inkjet or laser printers, and they are compatible with a wide range of materials, including cotton, polyester, and blends. Unlike sublimation paper, transfer paper does not require a coating to hold the ink; instead, the design is printed directly onto the paper and then transferred onto the substrate using a heat press.

There are two main types of transfer paper: light and dark. Light transfer paper is used for light-colored substrates and allows the color of the substrate to show through the design. Dark transfer paper contains an opaque layer that blocks the color of the substrate, making it suitable for dark-colored materials.

Differences Between Sublimation Paper and Transfer Paper

The primary difference between sublimation paper and transfer paper lies in their respective printing processes and the types of substrates they are compatible with. Sublimation paper, used exclusively with sublimation inks, is ideal for polyester and polymer-coated substrates, offering vibrant colors and durability due to the ink’s integration into the material. Transfer paper, usable with a broader range of inks and printers, is more versatile regarding substrate compatibility but may result in prints that feel more like a layer on top of the substrate.

Another significant difference is the durability of the transferred design. Sublimation prints are known for their long-lasting qualities, as the dye becomes part of the substrate. In contrast, designs transferred using transfer paper may crack, fade, or peel over time, especially with frequent washing or use.

Applications and Suitability

Choosing between sublimation paper and transfer paper depends on the specific needs of the project, including the desired outcome, the material of the substrate, and the available printing equipment. Sublimation printing is preferred for high-quality apparel, promotional items, and signage that require durability and resistance to fading. Transfer printing, with its broader material compatibility, is suited for short-term applications, custom gifts, and projects where the substrate is not compatible with sublimation ink.

Conclusion

While sublimation paper and transfer paper serve similar purposes in the world of custom printing, their distinct characteristics make them suitable for different applications. Understanding the differences between these two types of paper is crucial for selecting the right printing method for any given project. By choosing the appropriate paper and printing technique, individuals and businesses can achieve high-quality, durable prints tailored to their specific needs and preferences.